Surface facilities

Overview

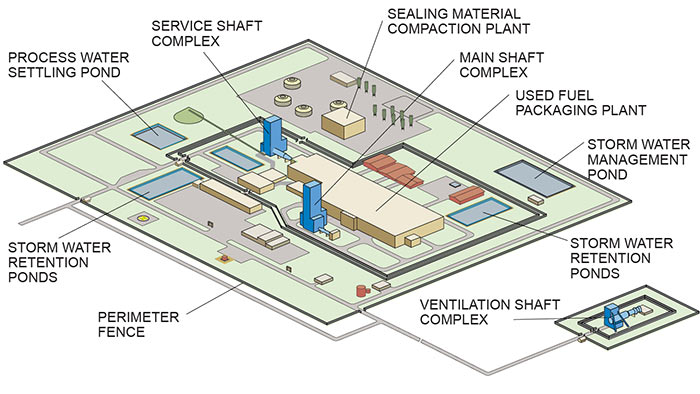

Layout of surface facilities for Canada's deep geological repository

Ensuring safety and security

To ensure safety and security, the following facilities will be developed on the site where the deep geological repository is located:

- Security Monitoring Stations

- Fire Hall

- Quality Control Offices

- Laboratories

- Active Waste Handling

- Storm Water Management Ponds

- Process Water Management Ponds

- Two levels of fences (around the site perimeter and around the Protected Area)

Used fuel packaging plant

The used fuel packaging plant will include all necessary areas and equipment for:

- Receiving used fuel transportation packages from interim storage sites;

- Receiving empty used fuel containers;

- Loading used fuel into repository containers; and

- Sealing, inspecting and dispatching filled containers for underground transfer and placement in the repository.

A conceptual layout of a used fuel packaging plant has been developed for planning and costing purposes. It consists of a reinforced concrete structure measuring about 125 metres by 65 metres. It can transfer about 120,000 used fuel bundles per year.

Sealing material compaction plant and concrete batch plant

Shafts and hoists

The main shaft conveys used fuel containers within a shielded transfer cask. The service shaft conveys personnel, equipment, waste rock and sealing materials. The ventilation shaft receives the majority of the repository exhaust and is equipped with a hoist for emergency exit for personnel.

Excavated rock management area

A large amount of rock will be excavated to create the repository. An excavated rock management area could require a surface area of about 460 metres by 380 metres, with a height of 15 metres. The footprint, height and location(s) of excavated rock could be planned in a way that takes into account community preferences. A portion of the excavated rock may be used in backfilling and sealing operations. The remaining rock may have a public or commercial use as aggregate for construction.

The excavated rock management area is currently assumed to be located off-site. Its size and location will be determined in collaboration with the host community and surrounding area.

Canada's deep geological repository

The repository design uses a multiple-barrier system. A series of engineered and natural barriers work together to contain and isolate used nuclear fuel from people and the environment.