Multiple-barrier system

Overview

Each barrier acts as part of the system, but also provides a unique and stand-alone level of protection. If any of the barriers deteriorates, the next one comes into play.

Watch now

Explore the multiple-barrier system

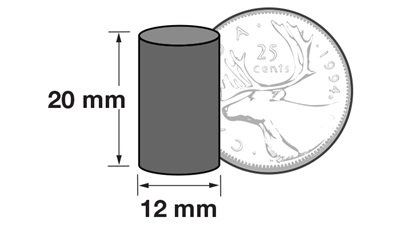

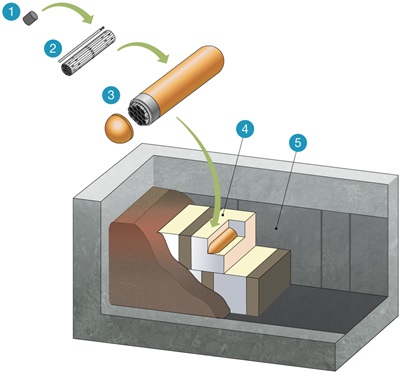

Barrier 1: The nuclear fuel pellet

The first barrier in the multiple-barrier system is the fuel pellet. Fuel pellets are made from uranium dioxide powder, a ceramic material, which is baked in a furnace to produce a hard, high-density pellet. Ceramics are extremely durable: they do not readily dissolve in water, and their resistance to wear and high temperatures make them one of the most durable engineered materials.

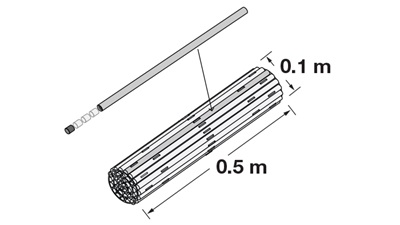

Barrier 2: The fuel element and the fuel bundle

Each fuel bundle is composed of a number of sealed tubes called fuel elements. Fuel elements contain the fuel pellets and are made of a strong, corrosion-resistant metal called Zircaloy. The function of each element is to contain and isolate the fuel pellets.

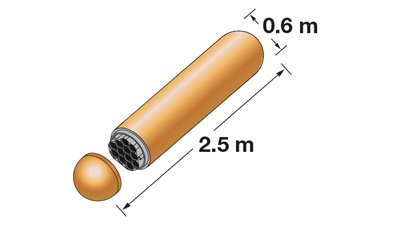

Barrier 3: The used nuclear fuel container

Used nuclear fuel bundles will be placed into large, very durable containers. In 2014, we refined our container design to one that is optimized for the used CANDU fuel produced by Canadian nuclear power reactors. Together with the bentonite clay buffer box (Barrier 4), the container is a key part of the engineered-barrier system.

The container prevents any water near the container from reaching the fuel and radionuclides. It is engineered to remain intact and keep the used nuclear fuel completely isolated until the fuel’s radioactivity has decreased to the level of natural uranium.

Each used nuclear fuel container holds 48 bundles loaded into 12 carbon steel channels or tubes, known as the container insert. The carbon steel container body has the mechanical strength to withstand pressure from the overlying rock as well as additional loading from three-kilometre-thick glaciers that may form during a future ice age. The carbon steel container head, which is welded to the container body, is spherical so that it will withstand these pressures as well.

The container is coated with copper to prevent corrosion. The copper coating and welding technologies used for this container design are based on proven technologies that are readily available in Canada. The used fuel container and supporting components will be manufactured at a container plant which could potentially be located in the host community or surrounding region, depending on interest.

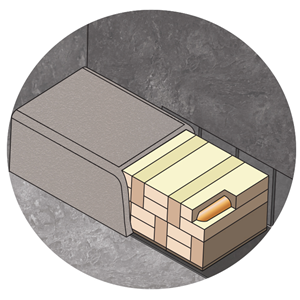

Barrier 4: Bentonite clay

During placement in the repository, each used nuclear fuel container will be encased in a highly compacted bentonite clay buffer box. Bentonite clay is a natural material proven to be a powerful barrier to water flow. It swells when exposed to water, making it an excellent sealing material.Bentonite is also very stable, as seen in natural formations formed millions to hundreds of millions of years ago. The chemical properties of the bentonite clay, backfill and sealants would help to isolate any radionuclides in the unlikely event they were to escape from the container. Each buffer box will be placed and separated from the next with bentonite clay spacer blocks. Containers will be stacked in two layers.

After the used nuclear fuel containers are placed in the repository, all open spaces in each underground chamber will also be filled with bentonite clay.

A six- to 10-metre-thick, highly compacted bentonite clay seal and a 10- to 12-metre-thick concrete bulkhead will be used to seal the entrance to each placement room.

Before closing the repository, tunnels and shafts will be filled with similar backfill and sealants, isolating the repository from the environment. The performance of the repository will be monitored during placement operations and during an extended postclosure period.

Barrier 5: The geosphere

The geosphere forms a natural barrier of rock which will protect the repository from disruptive natural events, water flow and human intrusion.The repository will be more than 500 metres underground; the exact depth will depend on the site. It will be excavated within a sedimentary or crystalline rock formation that meets the safety and technical requirements of the project. The rock formation selected will have low permeability, which means there will be little groundwater movement.

This natural barrier will ensure the repository safely contains and isolates the used nuclear fuel, even under extreme scenarios.

Full-scale emplacement trial

Watch now

Related documents

Related FAQs

View all FAQsAre the storage containers tested to ensure they won't leak?

Yes. The repository storage containers are part of a series of engineered and natural barriers that will work together to contain and isolate used nuclear fuel in the deep geological repository. They are made of thick, solid steel and welded shut. The steel provides the mechanical strength to withstand the pressures of the overlying rock and future glaciations. The outermost layer of the container consists of corrosion-resistant copper coating.

The containers will undergo non-destructive examination using ultrasonic high-frequency sound waves that can characterize thickness and internal structure, as well as surface testing to ensure there are no flaws in the weld or copper coating, confirming there are no leaks.

Can radiation leak from the underground repository?

The project cannot proceed without meeting strict requirements to ensure that radiation does not leak from the underground repository and that people and the environment are protected.

A multiple-barrier system of engineered and natural barriers will ensure the ongoing safety of the public and workers over the long term. These barriers include:

- The nuclear fuel pellet;

- The fuel element and fuel bundle;

- The used nuclear fuel container;

- Bentonite clay; and

- The geosphere — the host rock for the repository.

Each of these barriers provides a layer of protection so that if the performance of one degrades or is compromised, other barriers will still contain and isolate the used nuclear fuel.

The regulatory review of the repository will require a number of safety assessments that will look at a wide range of scenarios to ensure people and the environment are protected. "Disruptive scenarios" are conducted to test a range of hypothetical circumstances such as the impact of container failure at 10,000 or 60,000 years, or the failure of the seals within the repository shafts.

The safety case for the project must demonstrate with confidence that it will meet or surpass the stringent requirements of the regulatory authorities.

Will heat buildup in the repository create faults in the surrounding rock?

No. Some heat will be generated by radioactive decay; however, before being transported to the deep geological repository, the used nuclear fuel bundles will have cooled for decades in interim storage where the fuel was used.

On top of that, the repository design and safety case are developed to ensure temperatures generated will not influence the ability of the multiple-barrier system or the surrounding rock to contain and isolate the used nuclear fuel.

The repository layout and container spacing will prevent temperatures from going above 100 degrees Celsius on the container surface. The containers of used nuclear fuel will reach their highest temperatures less than 100 years after being placed in the repository. Temperatures will then gradually decrease to levels near those existing before repository construction.

The design of the repository will ensure this heat does not lead to faulting or create release pathways for radiation through the surrounding rock. Monitoring will ensure the facility is performing safely as designed.

Is there enough bentonite clay to meet the needs of the deep geological repository?

Yes. There is enough bentonite clay available to meet the needs of Canada's plan, as well as other used fuel repositories being planned around the world.

Bentonite clay is one of the barriers within the deep geological repository that will isolate the used nuclear fuel from people and the environment in the long term. The disposal containers are placed in bentonite clay as an additional seal. Bentonite clay will also be used to seal access tunnels, shafts and boreholes. It is a natural material that swells when exposed to water, making it an excellent sealing material. It is also very stable, as seen in natural formations formed millions to hundreds of millions of years ago.

The amount of bentonite clay to be used in the repository is about 40,000 tons per year over the 50-year operating life. Bentonite clay is formed from volcanic ash, and there are various suitable deposits around the world.

Bentonite clay is available in many countries around the world. Estimates for the worldwide production of bentonite range from 15,000,000 to 21,000,000 tons per year in recent years. It is estimated that Canada's deep geological repository would consume one to two per cent of the annual capacity in North America. Worldwide, deep geological repositories that are planned or expected will only consume about five to six per cent of the global bentonite supply.

The most likely source for the NWMO repository would be bentonite clay from Wyoming.